Ultrafine finishing thanks to homogeneous grain sizes

Premium microabrasives of consistent quality are required to achieve constant, reproducible technical surfaces. Products with micro technology from sia Abrasives ensure this unique grain calibration for an efficient CR-Finishing® (Constant Result) process.

Electrostatic coated abrasives

Coated abrasives are electrostatically coated on a cloth or paper backing.

Elutriated microabrasives

A microabrasive is produced using an elutriated manufacturing process. This involves embedding multiple fine layers of grit in the binder resin and applying them together to a polyester film.

All grits made with this process meet the CIS standard (Calibration for Industrial Standards), which stipulates that each grain is not allowed to exceed the nominal size in terms of width and also height. Consistent, reproducible machining can be ensured only by both controlled sizes.

CR-Finishing®

CR-Finishing® is a quality concept aimed at ensuring an efficient process which produces functional surfaces first time.

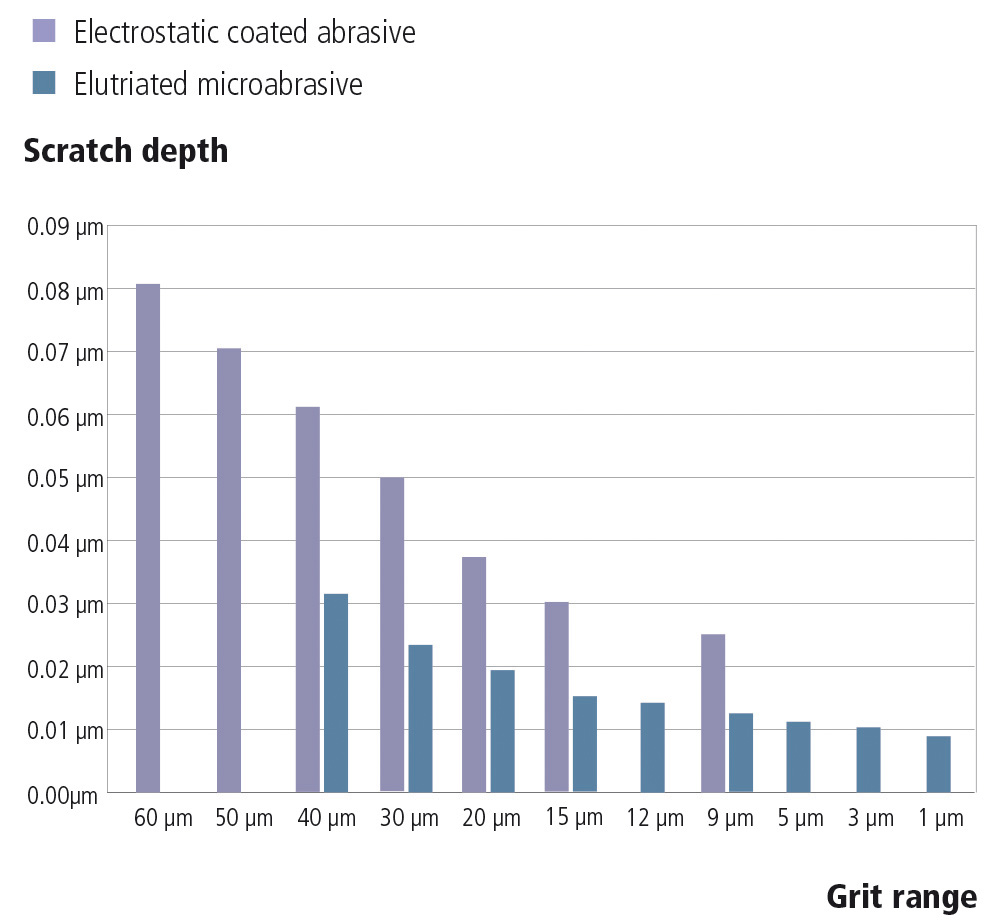

Performance comparison

- Chrome roller Ø 40 mm x 250 mm length

- Cutting speed: 12 cm/min

- Speed: 550 rpm

- Axial feed: 2.5 m/min

- Transitions: 2 x 2

- Contact roller: rubber, 655hA

- Oscillation: 30 Hz

- Contact pressure: 3 bar